Tereos Aalst is part of the international group Tereos Starch & Sweeteners, the third largest sugar producer in the world. Tereos’s biggest problem is the factory’s location in the centre of Aalst, where 150 to 180 trucks are processed daily.

Frank Pannecoucke, Group Supply Chain Manager, explains how Peripass provides specific solutions for the site. “We work with just-in-time loading to prevent trucks from getting stuck in the city centre. That is why we try to control the logistics flow as much as possible according to the factory capacity. We use Peripass to call up the trucks and manage the capacity on the site.”

“The current logistics flow is handled in collaboration with an external partner who receives and cleans the trucks and then prepares them for loading by Tereos. We use Peripass to determine which trucks are called and in which order to come and load at a specific time. The difficulty is that during the transfer from the third party to Tereos, the trucks are subject to unpredictable traffic conditions, which can cause delays at any time of the day. This generates uncertainty about the arrival times of the trucks, and we have no place in the centre of the city to create an extra waiting zone to buffer the trucks. That is why the buffering is done by our external partner. We call off the available trucks according to the loading capacity and the workload in the factory.”

“The three main reasons to choose Peripass: safety, the need to know who is on the site and the ability to send live information to the drivers.”

“Until last year, the trucks were called up using the Transwide transport management platform. That is a communication platform mainly for carriers to pass on orders and reserve loading slots. Why did we switch to another system? On one hand, the platform was being managed by the external partner and not by Tereos itself. On the other hand, there is an acute need to be able to change the schedule in the course of the day depending on the capacity and possible traffic delays. And that was too complicated in Transwide. Moreover, Transwide was set up for one specific flow, the flow via our external partner.

However, we also have additional logistics flows that have not yet been digitized. That is why Tereos was looking for a solution and ended up with Peripass, who has often worked with Transwide for integrations. All flows are currently being further assessed to be translated into the Peripass platform.”

“There is an acute need to be able to change the schedule in the course of the day depending on the capacity”

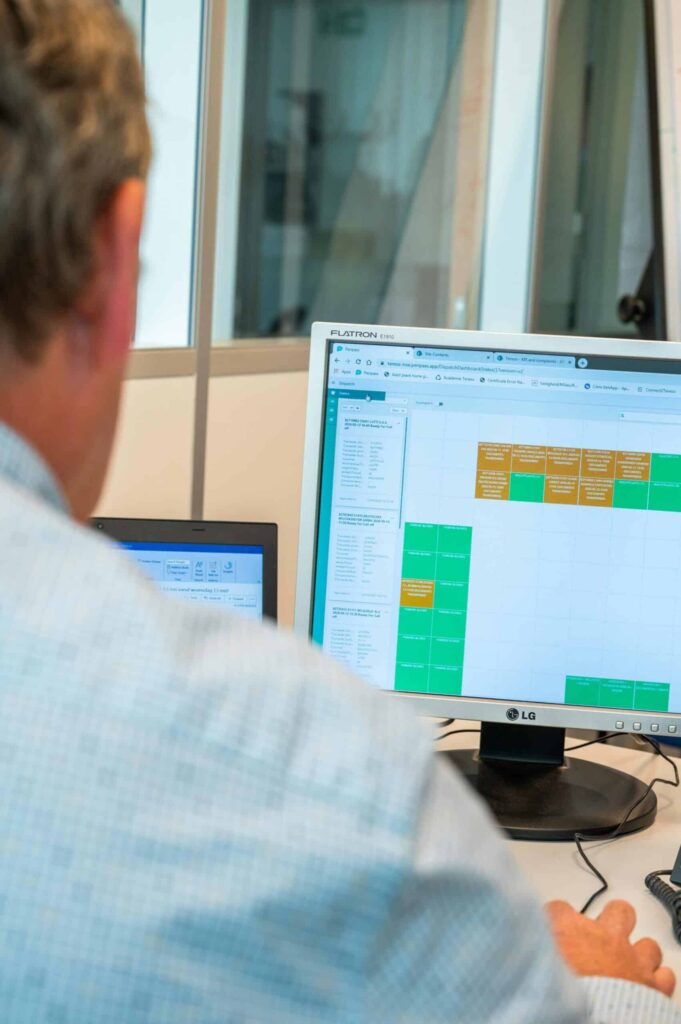

“The cleaned trucks wait to be called at the external partner’s site in a waiting parking lot. We can also see them in a virtual queue on the dispatch dashboard. The trucks are called based on this queue and in combination with the factory’s capacity. In the previous system, this is where an additional problem arose: the trucks were called completely manually. Tereos called the trucks in the Transwide system, and we had to trust that someone was literally seeing the call on their computer screen. After that, this operator had to notify the driver, and then the driver also had to receive the necessary papers, which could cause all kinds of delays.”

“One of our staff members had heard about a new system, so then we made an appointment with Peripass to find out how the platform worked. After an initial introduction, we were given a live demo with a different Peripass customer, Alpro (Danone Group), in Wevelgem. That also allowed us to see how Peripass was implemented and look at the trucks’ registration process at the waiting parking lot. Later on, in our preliminary talks, we were able to experience all the possibilities of using the platform ourselves in a test environment. The decision-makers who had seen the demo were the plant manager, quality manager, logistics manager and IT staff member. We were immediately convinced, and a few days later, we decided to start working with Peripass. Because of the functionality where the driver himself can automatically register. “

“Because the driver can enter his data into the system in real-time, including his personal details, we were able to close a gap in the registration process. In the past, we also had the drivers’ names, but that was it. Because we are a chemical company, we are responsible for what happens on the site, who is present on our premises, how long they stay and when they drive out again. If something happens, we can instantly trace it today thanks to the access control system of the Peripass platform. In addition, we want to implement an additional module in the registration process shortly: adding safety training for the drivers. This will be rolled out in the coming weeks after our internal staff has finished producing our safety film.”

“We were immediately convinced and a few days later we decided to start working with Peripass. Because of the functionality where the driver himself can automatically register”

In short, there were three important reasons why we initially chose Peripass: first and foremost, safety, in addition to the responsibility to know who is present on the site and for how long, and last, but at least as important, being able to send live information to the drivers. Working via SMS is more reliable than a manual process. We inform the driver in real-time about a specific changing status, so that he is better informed and can react much faster.

“The three main reasons to choose Peripass: safety, responsibility to know who is on the site and the ability to send live information to the drivers”

It is also an easy system to work with, and the platform’s responsiveness is good. We did not know this beforehand, but we were able to experience it first-hand. The software is built to be fairly easy to implement and can be deployed quickly.

Moreover, it is set up so that the people in the production department themselves (and not the dispatchers) can call up the trucks based on the situation in the factory. They determine who can enter and when. The vehicles that are expected on the site have a barcode that they scan at the entrance. They have the necessary loading documents with them, on which the barcode is printed. The barrier opens automatically when the barcode number matches the number in the system.”

“The basic programming of the logistics flows is done at Peripass. After delivery, we can make adjustments ourselves. I like to think of the dispatch dashboard like a box of toy building blocks because I can easily adjust blocks myself or add extra ones. That way, we are not dependent on an IT provider if we want to have something extra programmed or something adjusted. One of the major advantages of Peripass is that we can do all the adjustments ourselves. To give a few examples of what we have adjusted ourselves since the go-live: the number of loading locations, the blocking of specific loading docks, the renaming of loading locations, etc.”

“One of the major advantages of Peripass is that we can do all the adjustments ourselves”

“The reporting service has not yet been fully finalized. Currently, we do a dump of data, and then we work with pivot tables in Excel. To evaluate a past period, this type of analysis is something we will only start working on later. We use Peripass as a real-time platform. We can see live when someone is called, when he drives in, and how long he is on the site… That’s why we are a fan of Peripass, because we can view this live and adjust it if necessary. We mainly look at the operational follow-up. Evaluating the past periods will be for later. We use Peripass purely as a call system, but not yet as a total system for optimizing the flows.”

“We use Peripass as a real-time platform and can make adjustments if necessary. That’s why we are a fan of Peripass”

“We were lucky to decide a year and a half ago to work with Peripass. New rules have been imposed by the city council since the beginning of this year. And Peripass has helped us enormously in complying with them. Thanks to Peripass, we could comply very quickly with the city’s strict rules. We went live with Peripass on January 2. As early as January 5, we could consider the rush hour restrictions in our access flows when trucks do not have access to the city centre. By actively calling the trucks, we have the opportunity to ensure that no trucks arrive in a certain period of time. At the same time, the city council has requested insight into how we regulate the processes of giving access to the trucks. With Peripass, we can perfectly provide all the necessary feedback to show how we regulate our flows.”

“Currently, we don’t have total visibility of the flow. By this, I mean our external partner is a 30 to 45-minute drive from here. We always had that uncertainty due to manual actions: when the driver would leave the waiting zone, and when he would arrive here. Thanks to the automation of the system, informing the driver happens live, in combination with a trigger that ensures that we can see here when he leaves the waiting parking lot. This way, we can organize ourselves so that he can drive in almost immediately and leave loaded again half an hour later. As a result, the time the trucks spend here is considerably shorter. We expect to earn at least half an hour per truck thanks to automation. Today, the full turnaround time is 2h30 to 3h per truck (including transfer time between the waiting zone in Dendermonde and Tereos in Aalst). Thanks to Yard Automation, we can gain half an hour here. A significant time saver.

By giving the process operators total visibility, the factory can do just-in-time loading. This will improve the concentration of the number of trucks on the site because the time to load the truck will be greatly reduced.

Far fewer trucks on the site means increased safety in the factory for our own employees, but also safety for the surroundings.”

“Thanks to Yard Automation, we will be able to gain half an hour per transport”

Find out why companies like Bridgestone, Alpro, and Saint-Gobain use Peripass to manage their yards. Please fill out the form to see how our software works.